Product Description

| Product name | Precision Planetary Reducer |

| Model No. | AB42-AB220 |

| Layout form | Planetary structure |

| Speed ratio | 3-512 |

| Output torque | 20-1500N.M |

| Power | 50W~30KW |

| Input speed | 0~4000RPM |

| Output speed | 0~1300RPM |

| Output type | Shaft type |

| Installation | Flange mounting |

Product Description

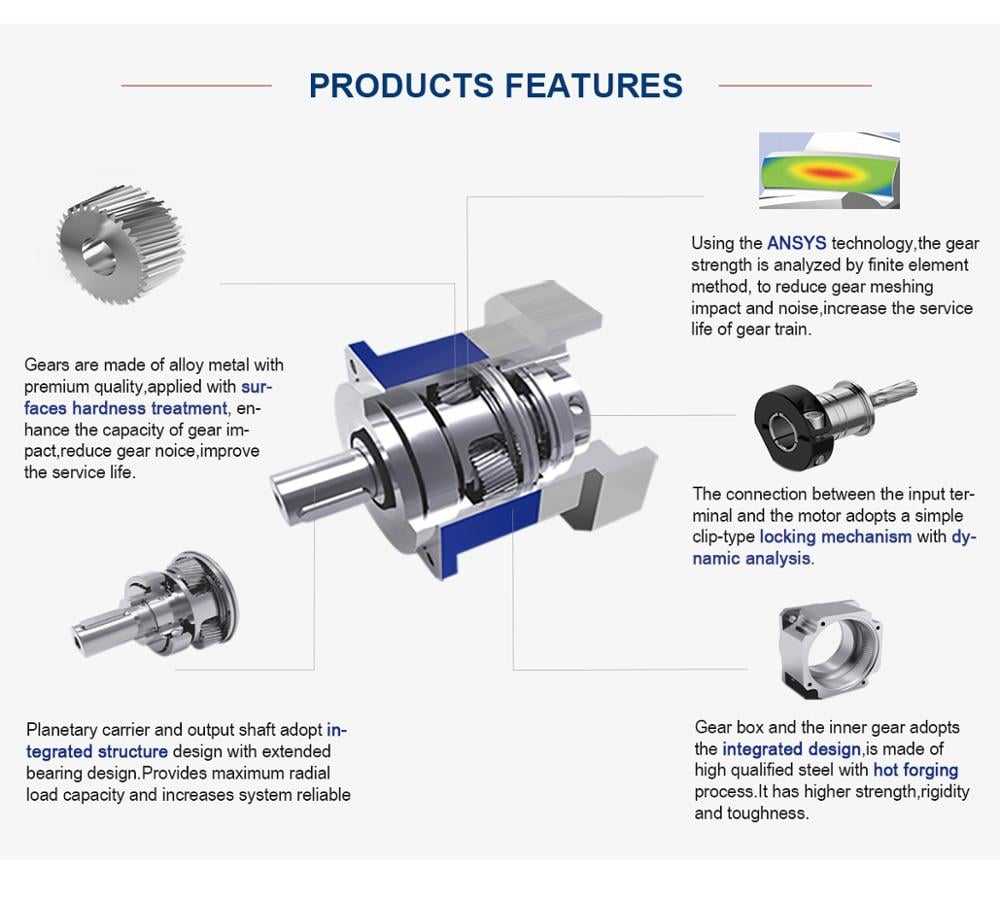

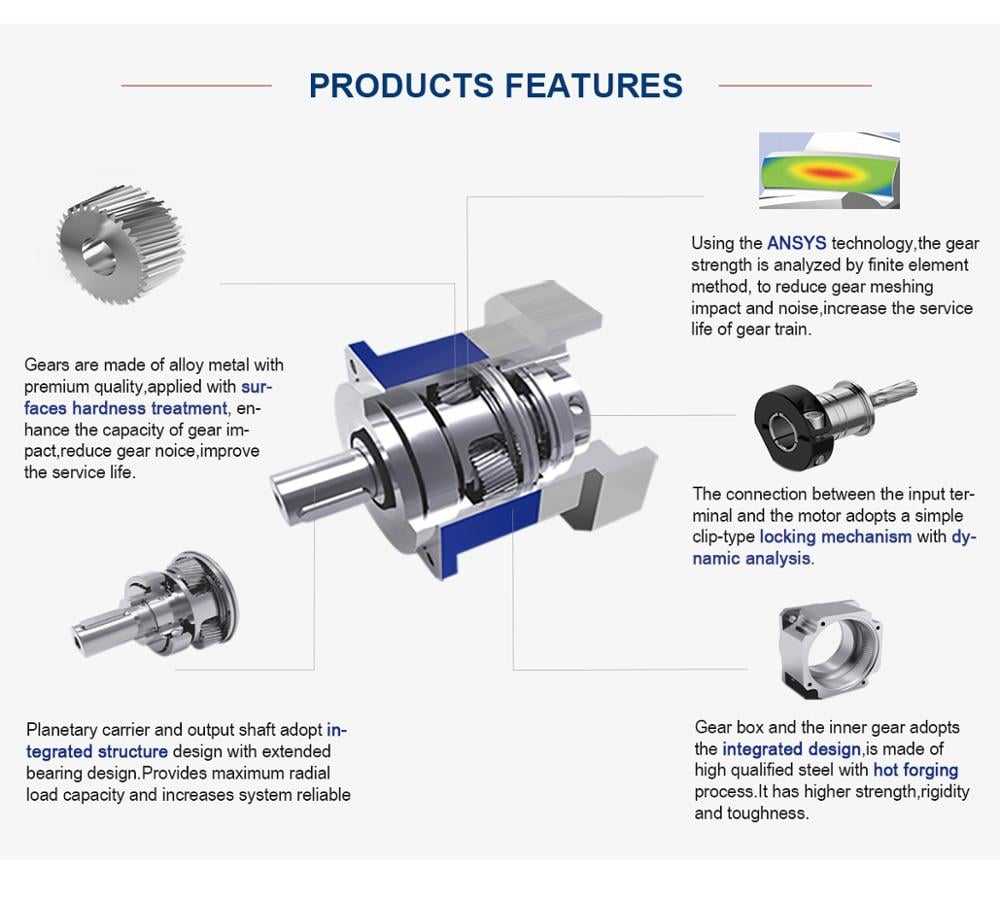

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

How to Compare Different Types of Spur Gears

When comparing different types of spur gears, there are several important considerations to take into account. The main considerations include the following: Common applications, Pitch diameter, and Addendum circle. Here we will look at each of these factors in more detail. This article will help you understand what each type of spur gear can do for you. Whether you’re looking to power an electric motor or a construction machine, the right gear for the job will make the job easier and save you money in the long run.

Common applications

Among its many applications, a spur gear is widely used in airplanes, trains, and bicycles. It is also used in ball mills and crushers. Its high speed-low torque capabilities make it ideal for a variety of applications, including industrial machines. The following are some of the common uses for spur gears. Listed below are some of the most common types. While spur gears are generally quiet, they do have their limitations.

A spur gear transmission can be external or auxiliary. These units are supported by front and rear casings. They transmit drive to the accessory units, which in turn move the machine. The drive speed is typically between 5000 and 6000 rpm or 20,000 rpm for centrifugal breathers. For this reason, spur gears are typically used in large machinery. To learn more about spur gears, watch the following video.

The pitch diameter and diametral pitch of spur gears are important parameters. A diametral pitch, or ratio of teeth to pitch diameter, is important in determining the center distance between two spur gears. The center distance between two spur gears is calculated by adding the radius of each pitch circle. The addendum, or tooth profile, is the height by which a tooth projects above the pitch circle. Besides pitch, the center distance between two spur gears is measured in terms of the distance between their centers.

Another important feature of a spur gear is its low speed capability. It can produce great power even at low speeds. However, if noise control is not a priority, a helical gear is preferable. Helical gears, on the other hand, have teeth arranged in the opposite direction of the axis, making them quieter. However, when considering the noise level, a helical gear will work better in low-speed situations.

Construction

The construction of spur gear begins with the cutting of the gear blank. The gear blank is made of a pie-shaped billet and can vary in size, shape, and weight. The cutting process requires the use of dies to create the correct gear geometry. The gear blank is then fed slowly into the screw machine until it has the desired shape and size. A steel gear blank, called a spur gear billet, is used in the manufacturing process.

A spur gear consists of two parts: a centre bore and a pilot hole. The addendum is the circle that runs along the outermost points of a spur gear’s teeth. The root diameter is the diameter at the base of the tooth space. The plane tangent to the pitch surface is called the pressure angle. The total diameter of a spur gear is equal to the addendum plus the dedendum.

The pitch circle is a circle formed by a series of teeth and a diametrical division of each tooth. The pitch circle defines the distance between two meshed gears. The center distance is the distance between the gears. The pitch circle diameter is a crucial factor in determining center distances between two mating spur gears. The center distance is calculated by adding the radius of each gear’s pitch circle. The dedendum is the height of a tooth above the pitch circle.

Other considerations in the design process include the material used for construction, surface treatments, and number of teeth. In some cases, a standard off-the-shelf gear is the most appropriate choice. It will meet your application needs and be a cheaper alternative. The gear will not last for long if it is not lubricated properly. There are a number of different ways to lubricate a spur gear, including hydrodynamic journal bearings and self-contained gears.

Addendum circle

The pitch diameter and addendum circle are two important dimensions of a spur gear. These diameters are the overall diameter of the gear and the pitch circle is the circle centered around the root of the gear’s tooth spaces. The addendum factor is a function of the pitch circle and the addendum value, which is the radial distance between the top of the gear tooth and the pitch circle of the mating gear.

The pitch surface is the right-hand side of the pitch circle, while the root circle defines the space between the two gear tooth sides. The dedendum is the distance between the top of the gear tooth and the pitch circle, and the pitch diameter and addendum circle are the two radial distances between these two circles. The difference between the pitch surface and the addendum circle is known as the clearance.

The number of teeth in the spur gear must not be less than 16 when the pressure angle is twenty degrees. However, a gear with 16 teeth can still be used if its strength and contact ratio are within design limits. In addition, undercutting can be prevented by profile shifting and addendum modification. However, it is also possible to reduce the addendum length through the use of a positive correction. However, it is important to note that undercutting can happen in spur gears with a negative addendum circle.

Another important aspect of a spur gear is its meshing. Because of this, a standard spur gear will have a meshing reference circle called a Pitch Circle. The center distance, on the other hand, is the distance between the center shafts of the two gears. It is important to understand the basic terminology involved with the gear system before beginning a calculation. Despite this, it is essential to remember that it is possible to make a spur gear mesh using the same reference circle.

Pitch diameter

To determine the pitch diameter of a spur gear, the type of drive, the type of driver, and the type of driven machine should be specified. The proposed diametral pitch value is also defined. The smaller the pitch diameter, the less contact stress on the pinion and the longer the service life. Spur gears are made using simpler processes than other types of gears. The pitch diameter of a spur gear is important because it determines its pressure angle, the working depth, and the whole depth.

The ratio of the pitch diameter and the number of teeth is called the DIAMETRAL PITCH. The teeth are measured in the axial plane. The FILLET RADIUS is the curve that forms at the base of the gear tooth. The FULL DEPTH TEETH are the ones with the working depth equal to 2.000 divided by the normal diametral pitch. The hub diameter is the outside diameter of the hub. The hub projection is the distance the hub extends beyond the gear face.

A metric spur gear is typically specified with a Diametral Pitch. This is the number of teeth per inch of the pitch circle diameter. It is generally measured in inverse inches. The normal plane intersects the tooth surface at the point where the pitch is specified. In a helical gear, this line is perpendicular to the pitch cylinder. In addition, the pitch cylinder is normally normal to the helix on the outside.

The pitch diameter of a spur gear is typically specified in millimeters or inches. A keyway is a machined groove on the shaft that fits the key into the shaft’s keyway. In the normal plane, the pitch is specified in inches. Involute pitch, or diametral pitch, is the ratio of teeth per inch of diameter. While this may seem complicated, it’s an important measurement to understand the pitch of a spur gear.

Material

The main advantage of a spur gear is its ability to reduce the bending stress at the tooth no matter the load. A typical spur gear has a face width of 20 mm and will fail when subjected to 3000 N. This is far more than the yield strength of the material. Here is a look at the material properties of a spur gear. Its strength depends on its material properties. To find out what spur gear material best suits your machine, follow the following steps.

The most common material used for spur gears is steel. There are different kinds of steel, including ductile iron and stainless steel. S45C steel is the most common steel and has a 0.45% carbon content. This type of steel is easily obtainable and is used for the production of helical, spur, and worm gears. Its corrosion resistance makes it a popular material for spur gears. Here are some advantages and disadvantages of steel.

A spur gear is made of metal, plastic, or a combination of these materials. The main advantage of metal spur gears is their strength to weight ratio. It is about one third lighter than steel and resists corrosion. While aluminum is more expensive than steel and stainless steel, it is also easier to machine. Its design makes it easy to customize for the application. Its versatility allows it to be used in virtually every application. So, if you have a specific need, you can easily find a spur gear that fits your needs.

The design of a spur gear greatly influences its performance. Therefore, it is vital to choose the right material and measure the exact dimensions. Apart from being important for performance, dimensional measurements are also important for quality and reliability. Hence, it is essential for professionals in the industry to be familiar with the terms used to describe the materials and parts of a gear. In addition to these, it is essential to have a good understanding of the material and the dimensional measurements of a gear to ensure that production and purchase orders are accurate.

editor by CX 2023-06-09

China Good quality KTS-060-L1-5 ratio 51 1 stage flange output planetary gearbox reducer for omron servo motor worm gearbox

Applicable Industries: Manufacturing Plant

Gearing Arrangement: Planetary

Output Torque: 40NM

Input Speed: 0-8000rpm

Output Speed: 3-2000rpm

Efficiendy: L1≥95, L2≥92

Protection Class: IP65

Life time: ≥20000 Hours

Operating temprature: -10℃- China

| Zhengming Transmission Science (HangZhou) Co.,Ltd Zhengming Transmission Science (HangZhou) co., LTD. is specialized in high-tech reducer, motor, and helical gear reducer, worm gear reducer, planetary reducer design research and development production in recent years, with the customers for the pursuit of product quality and price, High Torque NEMA 34 Planetary Gearbox Stepper Motor 8.5Nm 4.0A 4leads 2 Phase With Planetary Reducer Ratio 201 constantly in improving speed reducer of high performance to achieve maximum efficiency and provide a wide range of technical resources to do the unremitting efforts to adhere to quality first customer satisfaction and frequency sincere fetter business philosophy, constantly absorb professionals, the company always has a group of high-end technology to master the industry of science and technology talents with a positive and pragmatic style, the company drew on various advanced management experience to constantly improve itself and establish a good corporate culture. |

Synthesis of Epicyclic Gear Trains for Automotive Automatic Transmissions

In this article, we will discuss the synthesis of epicyclic gear trains for automotive automatic transmissions, their applications, and cost. After you have finished reading, you may want to do some research on the technology yourself. Here are some links to further reading on this topic. They also include an application in hybrid vehicle transmissions. Let’s look at the basic concepts of epicyclic gear trains. They are highly efficient and are a promising alternative to conventional gearing systems.

Synthesis of epicyclic gear trains for automotive automatic transmissions

The main purpose of automotive automatic transmissions is to maintain engine-drive wheel balance. The kinematic structure of epicyclic gear trains (EGTs) is derived from graph representations of these gear trains. The synthesis process is based on an algorithm that generates admissible epicyclic gear trains with up to ten links. This algorithm enables designers to design auto gear trains that have higher performance and better engine-drive wheel balance.

In this paper, we present a MATLAB optimization technique for determining the gear ratios of epicyclic transmission mechanisms. We also enumerate the number of teeth for all gears. Then, we estimate the overall velocity ratios of the obtained EGTs. Then, we analyze the feasibility of the proposed epicyclic gear trains for automotive automatic transmissions by comparing their structural characteristics.

A six-link epicyclic gear train is depicted in the following functional diagram. Each link is represented by a double-bicolor graph. The numbers on the graph represent the corresponding links. Each link has multiple joints. This makes it possible for a user to generate different configurations for each EGT. The numbers on the different graphs have different meanings, and the same applies to the double-bicolor figure.

In the next chapter of this article, we discuss the synthesis of epicyclic gear trains for automotive automatic transaxles. SAE International is an international organization of engineers and technical experts with core competencies in aerospace and automotive. Its charitable arm, the SAE Foundation, supports many programs and initiatives. These include the Collegiate Design Series and A World In Motion(r) and the SAE Foundation’s A World in Motion(r) award.

Applications

The epicyclic gear system is a type of planetary gear train. It can achieve a great speed reduction in a small space. In cars, epicyclic gear trains are often used for the automatic transmission. These gear trains are also useful in hoists and pulley blocks. They have many applications in both mechanical and electrical engineering. They can be used for high-speed transmission and require less space than other types of gear trains.

The advantages of an epicyclic gear train include its compact structure, low weight, and high power density. However, they are not without disadvantages. Gear losses in epicyclic gear trains are a result of friction between gear tooth surfaces, churning of lubricating oil, and the friction between shaft support bearings and sprockets. This loss of power is called latent power, and previous research has demonstrated that this loss is tremendous.

The epicyclic gear train is commonly used for high-speed transmissions, but it also has a small footprint and is suitable for a variety of applications. It is used as differential gears in speed frames, to drive bobbins, and for the Roper positive let-off in looms. In addition, it is easy to fabricate, making it an excellent choice for a variety of industrial settings.

Another example of an epicyclic gear train is the planetary gear train. It consists of two gears with a ring in the middle and the sun gear in the outer ring. Each gear is mounted so that its center rotates around the ring of the other gear. The planet gear and sun gear are designed so that their pitch circles do not slip and are in sync. The planet gear has a point on the pitch circle that traces the epicycloid curve.

This gear system also offers a lower MTTR than other types of planetary gears. The main disadvantage of these gear sets is the large number of bearings they need to run. Moreover, planetary gears are more maintenance-intensive than parallel shaft gears. This makes them more difficult to monitor and repair. The MTTR is also lower compared to parallel shaft gears. They can also be a little off on their axis, causing them to misalign or lose their efficiency.

Another example of an epicyclic gear train is the differential gear box of an automobile. These gears are used in wrist watches, lathe machines, and automotives to transmit power. In addition, they are used in many other applications, including in aircrafts. They are quiet and durable, making them an excellent choice for many applications. They are used in transmission, textile machines, and even aerospace. A pitch point is the path between two teeth in a gear set. The axial pitch of one gear can be increased by increasing its base circle.

An epicyclic gear is also known as an involute gear. The number of teeth in each gear determines its rate of rotation. A 24-tooth sun gear produces an N-tooth planet gear with a ratio of 3/2. A 24-tooth sun gear equals a -3/2 planet gear ratio. Consequently, the epicyclic gear system provides high torque for driving wheels. However, this gear train is not widely used in vehicles.

Cost

The cost of epicyclic gearing is lower when they are tooled rather than manufactured on a normal N/C milling machine. The epicyclic carriers should be manufactured in a casting and tooled using a single-purpose machine that has multiple cutters to cut the material simultaneously. This approach is widely used for industrial applications and is particularly useful in the automotive sector. The benefits of a well-made epicyclic gear transmission are numerous.

An example of this is the planetary arrangement where the planets orbit the sun while rotating on its shaft. The resulting speed of each gear depends on the number of teeth and the speed of the carrier. Epicyclic gears can be tricky to calculate relative speeds, as they must figure out the relative speed of the sun and the planet. The fixed sun is not at zero RPM at mesh, so the relative speed must be calculated.

In order to determine the mesh power transmission, epicyclic gears must be designed to be able to “float.” If the tangential load is too low, there will be less load sharing. An epicyclic gear must be able to allow “float.” It should also allow for some tangential load and pitch-line velocities. The higher these factors, the more efficient the gear set will be.

An epicyclic gear train consists of two or more spur gears placed circumferentially. These gears are arranged so that the planet gear rolls inside the pitch circle of the fixed outer gear ring. This curve is called a hypocycloid. An epicyclic gear train with a planet engaging a sun gear is called a planetary gear train. The sun gear is fixed, while the planet gear is driven.

An epicyclic gear train contains several meshes. Each gear has a different number of meshes, which translates into RPM. The epicyclic gear can increase the load application frequency by translating input torque into the meshes. The epicyclic gear train consists of 3 gears, the sun, planet, and ring. The sun gear is the center gear, while the planets orbit the sun. The ring gear has several teeth, which increases the gear speed.

Another type of epicyclic gear is the planetary gearbox. This gear box has multiple toothed wheels rotating around a central shaft. Its low-profile design makes it a popular choice for space-constrained applications. This gearbox type is used in automatic transmissions. In addition, it is used for many industrial uses involving electric gear motors. The type of gearbox you use will depend on the speed and torque of the input and output shafts.

in Nay Pyi Taw Myanmar sales price shop near me near me shop factory supplier Atg High Strength Speed Plate Planetary Reducer manufacturer best Cost Custom Cheap wholesaler

Total use has been manufactured of all varieties of advanced methods and technologies to achieve excelsior manufacturing. Thanks to our vast item assortment and prosperous experiences in this industry, EPG was awarded with “famous merchandise of Zhejiang Province” and “popular brand of Zhejiang Province”. PGF Sequence

Goods Attributes:

(one) Low Sounds:UnEPT65db.

(two) Reduced Backlash:Backlash is unEPT3 arcmin . Backlash for 2-phase pace reduction is with in five arcmin.

(3) Higher Efficiency:1-phase up to ninety five% or more,2-stage up to ninety two% or more.

(4) High Input Speed:Input velocity makes it possible for for up to 8000RPM.

(5) Substantial Torque:High torque output than that of standard planetary EPT EPTs

(6) Upkeep-Totally free:Low grease dress in,can be lifetime lubrication

(7) Substantial Pace Reduction Ratio:Pace ratio is over 1/one thousand.

Advantage:

Usage:

- Aerospace,military sector.

- Medical health,electronic details sector.

- Sector robots,Production EPT,CNC EPT instrument manufacturing business.

- EPT,Textile,EPT,Meals,EPTlurgical.

- EPT protection engineering,Warehouse EPT sector.

Product ILLUMINATE:

Equipment BOX Overall performance Details:

| MODUL NO. | Phase | RATIO sup1 | PGF42 | PGF60 | PGF90 | PGF115 | PGF142 | PGF180 | PGF220 | |

| Rated output torque T2N | Nm | 1 | four | 19 | 48 | 130 | 270 | 560 | 1,a hundred | 1,700 |

| 5 | 22 | 60 | 160 | 330 | 650 | one,200 | two,000 | |||

| 7 | 19 | 35 | one hundred forty | 300 | 550 | 1,a hundred | one,800 | |||

| 8 | seventeen | 35 | one hundred twenty | 260 | 500 | 1,000 | one,600 | |||

| 10 | 14 | 37 | 95 | 220 | 370 | 800 | one,220 | |||

| 2 | 20 | 19 | 37 | ninety five | 220 | 370 | 800 | 1,220 | ||

| 25 | 22 | sixty | 160 | 330 | 650 | 1,two hundred | two,000 | |||

| 35 | 22 | 60 | 160 | 330 | 650 | one,200 | 2,000 | |||

| 40 | 22 | sixty | one hundred sixty | 330 | 650 | 1,200 | 2,000 | |||

| 50 | 22 | sixty | a hundred and sixty | 330 | 650 | one,two hundred | 2,000 | |||

| 70 | 19 | 35 | one hundred forty | three hundred | 50 | 1,one hundred | 1,800 | |||

| one hundred | 14 | 37 | 95 | 220 | 370 | 800 | 1,220 | |||

| MAX. output torqueT2B | Nm | one,2 | four~one hundred | three occasions of Nominal Output Torque | ||||||

| Rated enter pace n1 | rpm | one,two | four~a hundred | 5,000 | 5,000 | 4,000 | 4,000 | 3,000 | 3,000 | two,000 |

| MAX.enter velocity n1B | rpm | 1,2 | 4~100 | ten,000 | 10,000 | 8,000 | 8,000 | 6,000 | 6,000 | 4,000 |

| Micro Backlash P0 | arcmin | 1 | 4~ten | – | – | le1 | le1 | le1 | le1 | le1 |

| 2 | twenty~one hundred | – | – | – | le3 | le3 | le3 | le3 | ||

| EPT Backlash P1 | arcmin | 1 | four~10 | le3 | le3 | le3 | le3 | le3 | le3 | le3 |

| two | twenty~a hundred | le5 | le5 | le5 | le5 | le5 | le5 | le5 | ||

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Backlash P2 | arcmin | one | four~10 | le5 | le5 | le5 | le5 | le5 | le5 | le5 |

| two | 20~a hundred | le7 | le7 | le7 | le7 | le7 | le7 | le7 | ||

| Torsional stiffness | Nm/arcmin | 1,2 | 4~one hundred | 7 | 13 | 31 | 82 | 151 | 440 | 1006 |

| Max.radial drive M2kB2 | Nm | one,two | four~one hundred | 43 | one hundred twenty five | 235 | 430 | one,300 | three,064 | five,900 |

| MAX.aXiHu (West Lake) Dis.al power F2B sup2 | N | one,2 | four~a hundred | 1,080 | 2,a hundred and ten | two,310 | 4,800 | six,200 | 5,450 | ten,600 |

| Support lifestyle | hr | one,2 | four~a hundred | twenty,000* | ||||||

| Operate performance eta | % | 1 | 4~10 | ge97 | ||||||

| 2 | 20~100 | ge94 | ||||||||

| Bodyweight | kg | 1 | 4~ten | .7 | 1.two | 3 | five.six | 11.nine | 31.6 | 56.1 |

| 2 | twenty~one hundred | 1 | one.6 | three.7 | 7.three | 15.9 | 36.nine | 70.four | ||

| Running temperature | ordmC | one,two | 4~a hundred | -ten ordmC~ ninety ordmC | ||||||

| Lubrication | one,two | 4~100 | Synthetic lubricating oil | |||||||

| Safety stage | 1,2 | four~a hundred | IP65 | |||||||

| Set up course | 1,2 | 4~one hundred | Any direction | |||||||

| Sound level(n1=3000rpm) | dB | one,2 | 4~a hundred | le56 | le58 | le60 | le63 | le65 | le67 | le70 |

Outline DIMENSION:

Firm See:

HangEPT EPEPTndeyi EPT amp Electrical Co., Ltd. is a subsidiary of EPTiwan Jun Yi EPTry. Jun Yi EPTry was founded in March 1972. The company EPTizes in the style, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and manufacturing of substantial-tech different EPTed motors and helical EPT EPTs, worm and worm EPT EPTs and planetary EPTs. Our products offered to more than 30 nations around the world around the planet and earn great popularity and many awards in the overEPT market place for many a long time. In recent a long time, to attain EPT generation and give superb service,we established up subsidiary of generation of planetary EPT EPT in EPT.

History:

1972:EPTiwan Jun Yi EPTry is established.

1989:It estabEPTd a overEPT branch firm ATRUMP EPTRY INC in Los Angeles

1995:Go the ISO9002 Commodity certification.

2003:Move the ISO9001 quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd test which enabled the items to be offered in Europe

2013:The firm established up subsidiary in EPT to accomplish EPT production.

Manufacturing facility:

Wisdom Manufactured In ATG,Knowledge The EPT.

Gear:

INSPECTION Equipment:

FAQ:

(1) Can I be your agent?

Yes, welcome to deep cooperation. We have big advertising of ATG manufacturer in the industry now. For the details please contact me.

(2) Is OEM accessible?

Of course, OEM is offered. We have skilled designer to support your manufacturer promotion.

(3) How can I get a sample to examine your high quality?

Right after price confirmation, you can require for samples to examine our good quality. Cost-free for the samples, but you need to have to pay for the freight.

(four)What is actually your top quality promise?

We have different kinds of products which can satisfy different high quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC division will take a look at items ahead of shipping and delivery. We have a hundred% good quality ensure to consumers. We will be accountable for any top quality issue.

(5) How about the delivery time?

The delivery time is depending on the goods and the quantity. But EPTly, the shipping and delivery time for a container is about one particular month.

Welcome to our business.

If any dilemma, come to feel cost-free to go away message on the bottom of this website page.

in Port-au-Prince Haiti sales price shop near me near me shop factory supplier Atg Orthogonal Plate Type Planetary Gear Reducer manufacturer best Cost Custom Cheap wholesaler

The team is focused on creating all range of standard roller chains and sprockets, gears & gearboxes, these kinds of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just marketed its items all more than china, but also marketed more than 65% products to oversees, including Europe, The united states, South-east Asia, and it also has established up storage logistics in places like Europe. Our major merchandise are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical simple bearings, Observe roller Bearings for Guideway, Roller Bearings, Merge Bearings for forklifts, H2o Pump Bearings, SNR Car Bearings and all varieties of Spherical Bearings. If you require any data or samples, make sure you make contact with us and you will have our before long reply. PGF Series

Items Functions:

(1) Low Sound:UnEPT65db.

(2) Low Backlash:Backlash is unEPT3 arcmin . Backlash for 2-phase pace reduction is with in 5 arcmin.

(3) Large Efficiency:1-stage up to ninety five% or more,2-phase up to 92% or far more.

(four) Higher Input Velocity:Enter pace enables for up to 8000RPM.

(5) Higher Torque:Higher torque output than that of conventional planetary EPT EPTs

(6) Upkeep-Free:Reduced grease dress in,can be lifetime lubrication

(7) Higher Speed Reduction Ratio:Pace ratio is above 1/one thousand.

Edge:

Use:

- Aerospace,navy sector.

- Medical wellness,electronic information business.

- Market robots,Production EPT,CNC EPT device producing sector.

- EPT,Textile,EPT,Meals,EPTlurgical.

- EPT protection engineering,Warehouse EPT market.

Model ILLUMINATE:

Gear BOX Overall performance Data:

| MODUL NO. | Phase | RATIO sup1 | PGF42 | PGF60 | PGF90 | PGF115 | PGF142 | PGF180 | PGF220 | |

| Rated output torque T2N | Nm | 1 | four | 19 | forty eight | a hundred thirty | 270 | 560 | one,100 | one,seven-hundred |

| 5 | 22 | 60 | a hundred and sixty | 330 | 650 | 1,two hundred | two,000 | |||

| seven | 19 | 35 | 140 | 300 | 550 | one,one hundred | 1,800 | |||

| 8 | 17 | 35 | one hundred twenty | 260 | 500 | one,000 | one,600 | |||

| 10 | fourteen | 37 | 95 | 220 | 370 | 800 | 1,220 | |||

| 2 | 20 | 19 | 37 | ninety five | 220 | 370 | 800 | 1,220 | ||

| twenty five | 22 | sixty | a hundred and sixty | 330 | 650 | one,200 | two,000 | |||

| 35 | 22 | sixty | one hundred sixty | 330 | 650 | one,two hundred | 2,000 | |||

| 40 | 22 | sixty | one hundred sixty | 330 | 650 | one,200 | 2,000 | |||

| 50 | 22 | 60 | one hundred sixty | 330 | 650 | one,two hundred | two,000 | |||

| 70 | 19 | 35 | 140 | 300 | 50 | 1,a hundred | one,800 | |||

| 100 | fourteen | 37 | ninety five | 220 | 370 | 800 | 1,220 | |||

| MAX. output torqueT2B | Nm | 1,2 | 4~a hundred | 3 moments of Nominal Output Torque | ||||||

| Rated enter velocity n1 | rpm | one,2 | 4~one hundred | five,000 | five,000 | four,000 | four,000 | three,000 | three,000 | two,000 |

| MAX.input speed n1B | rpm | one,2 | 4~one hundred | 10,000 | 10,000 | eight,000 | 8,000 | six,000 | six,000 | 4,000 |

| Micro Backlash P0 | arcmin | one | four~10 | – | – | le1 | le1 | le1 | le1 | le1 |

| two | 20~100 | – | – | – | le3 | le3 | le3 | le3 | ||

| EPT Backlash P1 | arcmin | 1 | 4~ten | le3 | le3 | le3 | le3 | le3 | le3 | le3 |

| 2 | twenty~a hundred | le5 | le5 | le5 | le5 | le5 | le5 | le5 | ||

| StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd Backlash P2 | arcmin | one | 4~10 | le5 | le5 | le5 | le5 | le5 | le5 | le5 |

| 2 | twenty~one hundred | le7 | le7 | le7 | le7 | le7 | le7 | le7 | ||

| Torsional stiffness | Nm/arcmin | one,2 | 4~one hundred | seven | thirteen | 31 | 82 | 151 | 440 | 1006 |

| Max.radial power M2kB2 | Nm | 1,two | 4~one hundred | 43 | one hundred twenty five | 235 | 430 | 1,300 | three,064 | five,900 |

| MAX.aXiHu (West Lake) Dis.al power F2B sup2 | N | 1,2 | four~a hundred | 1,080 | 2,a hundred and ten | 2,310 | four,800 | six,200 | 5,450 | 10,600 |

| Support life | hr | 1,2 | four~one hundred | twenty,000* | ||||||

| Work effectiveness eta | % | 1 | four~ten | ge97 | ||||||

| two | twenty~100 | ge94 | ||||||||

| Fat | kg | one | 4~ten | .seven | one.2 | three | five.six | eleven.9 | 31.6 | 56.1 |

| two | 20~a hundred | 1 | 1.six | three.7 | seven.three | fifteen.nine | 36.9 | 70.4 | ||

| Functioning temperature | ordmC | 1,2 | four~one hundred | -10 ordmC~ 90 ordmC | ||||||

| Lubrication | one,two | 4~a hundred | Synthetic lubricating oil | |||||||

| Defense stage | 1,two | 4~a hundred | IP65 | |||||||

| Installation direction | 1,2 | 4~100 | Any direction | |||||||

| Sounds stage(n1=3000rpm) | dB | one,2 | 4~100 | le56 | le58 | le60 | le63 | le65 | le67 | le70 |

Define DIMENSION:

Business Check out:

HangEPT EPEPTndeyi EPT amp Electrical Co., Ltd. is a subsidiary of EPTiwan Jun Yi EPTry. Jun Yi EPTry was established in March 1972. The company EPTizes in the layout, deveXiHu (West Lake) Dis.Hu (West Lake) Dis.ment and generation of substantial-tech different EPTed motors and helical EPT EPTs, worm and worm EPT EPTs and planetary EPTs. Our goods bought to more than 30 nations around the entire world and earn excellent reputation and numerous awards in the overEPT marketplace for a lot of several years. In current many years, to achieve EPT generation and give outstanding services,we established up subsidiary of production of planetary EPT EPT in EPT.

Heritage:

1972:EPTiwan Jun Yi EPTry is established.

1989:It estabEPTd a overEPT department firm ATRUMP EPTRY INC in Los Angeles

1995:Go the ISO9002 Commodity certification.

2003:Pass the ISO9001 high quality certification and the European CE stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd take a look at which enabled the goods to be offered in Europe

2013:The firm set up subsidiary in EPT to accomplish EPT generation.

Manufacturing unit:

Wisdom Manufactured In ATG,Knowledge The EPT.

Tools:

INSPECTION Tools:

FAQ:

(1) Can I be your agent?

Indeed, welcome to deep cooperation. We have massive promotion of ATG manufacturer in the industry now. For the information please contact me.

(two) Is OEM obtainable?

Of course, OEM is offered. We have professional designer to support your model promotion.

(3) How can I get a sample to check out your quality?

Right after price tag affirmation, you can call for for samples to check out our high quality. Free of charge for the samples, but you need to pay for the freight.

(four)What is actually your good quality promise?

We have distinct types of merchandise which can meet up with diverse quality stXiHu (West Lake) Dis.Hu (West Lake) Dis.rd.

Our QC office will examination products ahead of transport. We have a hundred% good quality assure to clients. We will be responsible for any quality issue.

(five) How about the supply time?

The delivery time is relying on the products and the amount. But EPTly, the shipping time for a container is about 1 thirty day period.

Welcome to our organization.

If any difficulty, feel free to depart message on the bottom of this website page.

Best China manufacturer & factory china in Chittagong Bangladesh manufacturer BAB060 5000rpm 10:1 ratio zero backlash precision planetary gear box reducer With high quality best price

Having accrued treasured encounter in cooperating with international buyers, a specialized provider of a entire variety of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Particulars

- Applicable Industries:

-

CNC

- Gearing Arrangement:

-

Planetary

- Output Torque:

-

forty~60 N.m

- Input Pace:

-

5000rpm

- Output Velocity:

-

*

- Location of Origin:Zhejiang, China

- Brand name Title:

-

OEM

- Item title:

-

planetary gear reducer

- Substance:

-

20CrMnTi, 40Cr

- Ratio:

-

three-10

- Backlash:

-

P2

A worm push produces a large gearing ratio in a compact size. For every single rotation of the worm gear shaft, the output radial equipment rotates by only 1 tooth. The output push shaft is at ninety levels to the input shaft.

- Ingress protection:

-

IP65

In our organization we are aware of the significance of the users’ protection. Which is why our PTO’s are created according to lawful regulations and European directives and bear the CE indicator. A important aspect for security assurance is the accession in the products’ advancement stage. By all means, the users’ knowledge about the right use of a PTO travel shaft is crucial. This signifies, that every users’ responsibility is to study and follow the security directions.

- Shade:

-

champagne gold+black/ silver+blue/ OEM shade

- Warmth treatment:

-

very hot solid/hardening

Source Capacity

- Offer Capability:

- 200000 Piece/Pieces for each Month

Packaging & Shipping and delivery

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Quantity(Parts) one – 1000 >1000 Est. Time(times) 30 To be negotiated

Online Customization

At any time-electrical power Group Co., Ltd. is Specialist IN Creating ALL Varieties OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Speed REDUCERS, PARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Drive SHAFTS, Specific REDUCER & Relevant Equipment Parts AND OTHER Relevant Products, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Pace VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Reduced BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Generate Custom-made VARIATORS, GEARED MOTORS, Electric MOTORS AND OTHER HYDRAULIC Items According TO Consumers DRAWINGS.

HangZhou At any time-PowerMechanical & Electrical Co., Ltd. is a specialist company ofgearbox and motors.The factory covers an region of twenty,000 square meters, the constructing area of 30,000 square meters, the total quantity of staff is more than two hundred .We have handed theISO9001:2015intercontinental good quality administration technique common certificate,CCCnational obligatory item certificate andCEcertification . We have developed advanced management computer software such asERPto preserve rate with global standard.In get to serve consumers greater the organization actively cooperates with colleges and universities to develop new merchandise and enhance existing products .

|

Q1. Are you buying and selling organization or producer? A. We are manufacturer Found in Taizhou City of East China. Q2. How is assure of the high quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and report substance and semi-concluded spare elements. And – 100% inspect concluded spare elements ahead of put in storage. – 100% examine ahead of assembly. – 100% examine just before packaging. Q3. What information shall we give just before positioning a acquire buy? We can source complex assistance and the drawing in accordance to your necessity if you make contact with with me. Q4. What industries are your gearboxes currently being utilised? Our gearboxes are broadly utilised in the places of textile, food processing, beverage, chemical sector,escalator,automated storage tools, metallurgy, tabacco, environmental protection, logistics and and many others. Q5. Do you have warranty support? Of course, the gearbox is free of charge guarantee inside 1 several years following shipping. |

||||||

Primary goods incorporate: manure spreading truck, potato planting/harvesting device, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, blend rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its equipment: Plow disc blades, harrowing movie, plough idea and share, cultivator tine, casting components etc.